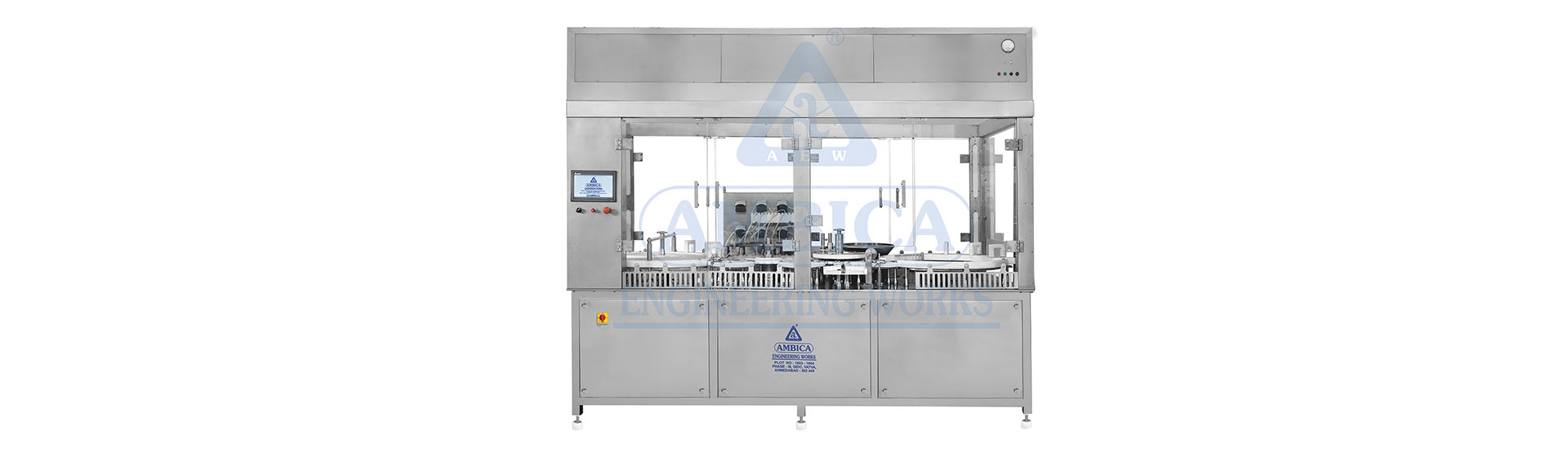

| Model no | AEW-RG-150SC | ARE-RG-300SC | AEW-RG-400SC |

|---|---|---|---|

| Speed of machine | Up to 150 /minute | Up to 300/minute | Up to 400/minute |

| Size of contain | 1 ml to 25 ml ampoule Up to 10 ml vial |

1 ml to 25 ml ampoule Up to 10 ml vial |

1 ml to 25 ml ampoule Up to 10 ml vial |

| Height | 900 mm (50 mm +/- adjustable) | 900 mm (50 mm +/- adjustable) | 900 mm (50 mm +/- adjustable) |

| Sensors | No ampoule no filling, no vial no rubber stoppering |

No ampoule no filling, no vial no rubber stoppering |

No ampoule no filling, no vial no rubber stoppering |

| Model no | AEW-RG-120 | AEW-RG-250 |

|---|---|---|

| Speed of machine | Up to 120 vials per minute | Up to 250 vials per minute |

| Size of contains | 5 ml vial to 100 ml vials | 5 ml vial to 100 ml vials |

| Capacity | 50 mg to 1500 mg (single dose ) 1500 mg to 6000 mg multiple dose ie-2,3,4,5) |

50 mg to 1500 mg (single dose ) 1500 mg to 6000 mg multiple dose ie-2,3,4,5) |

| Sensors | No vial no fill, no vial no stopper, no rubber machine stop 100% servo based operating system |

No vial no fill, no vial no stopper, no rubber machine stop 100% servo based operating system |

| Height | 900 mm (50 mm +/- adjustable) | 900 mm (50 mm +/- adjustable) |

| Model no | AEW-RG-150 | AEW-RG-300 | ARE-RG-400 |

|---|---|---|---|

| Speed Of Machine | Up To 150 Vials/Minute | Up To 300 Vials/Minute | Up To 400 Vials/Minute |

| Size of contains | 2 ml to 500 ml vial/bottle | 2 ml to 500 ml vial/bottle | 2 ml to 500 ml vial/bottle |

| Sensors | No vial no stoppering , no vial no filling |

No vial no stoppering , no vial no filling |

No vial no stoppering , no vial no filling |

| Height | 900 mm (50 mm +/- adjustable) | 900 mm (50 mm +/- adjustable) | 900 mm (50 mm +/- adjustable) |